Maximizing Success in the Beverages Industry: The Power of a Modern Beverages Factory

Introduction: The Vital Role of a Beverages Factory in Modern Business

In today’s competitive beverage market, establishing an efficient and innovative beverages factory is crucial for any business aiming to excel in the beverage store industry. A beverages factory not only serves as the heart of production but also acts as a catalyst for expanding product lines, maintaining high-quality standards, and ensuring consistent supply to meet consumer demands.

The evolution of beverage manufacturing has seen a shift towards highly automated, technologically advanced factories that emphasize quality, sustainability, and scalability. These factories are the backbone of thriving beverage brands and are instrumental in helping businesses outperform competitors in search rankings by delivering superior content, product variety, and customer satisfaction.

Defining a Beverages Factory: The Cornerstone of Beverage Manufacturing

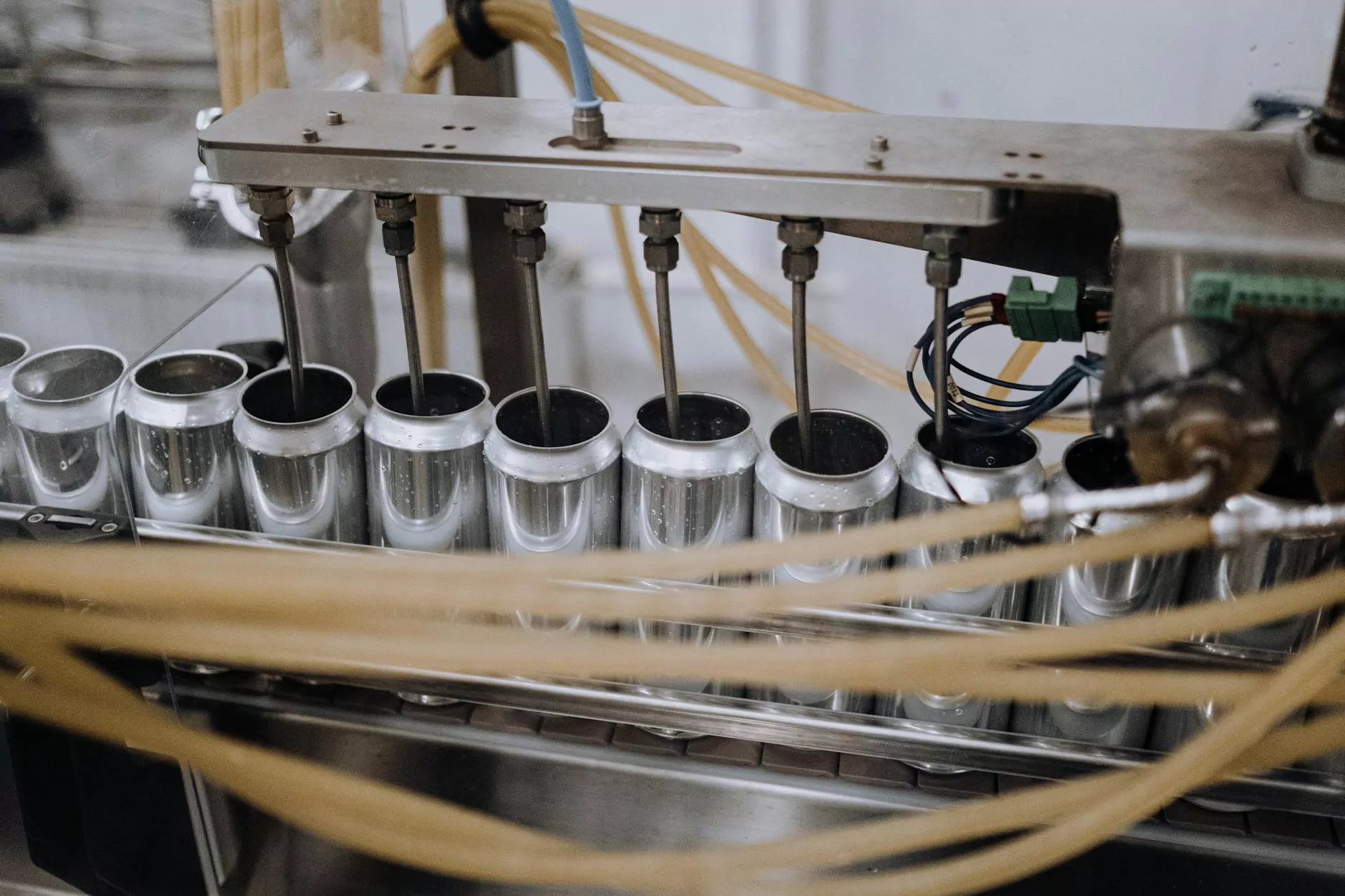

A beverages factory is a dedicated facility where beverages—ranging from soft drinks and bottled water to energy drinks and functional beverages—are produced, packaged, and prepared for distribution. Such factories are equipped with advanced machinery for mixing, carbonation, pasteurization, filling, and sealing, ensuring that each product meets stringent quality standards.

Modern beverages factories are designed with an emphasis on efficiency and sustainability. This includes integrating eco-friendly practices such as waste reduction, energy-efficient equipment, and environmentally safe packaging materials, which appeal to increasingly eco-conscious consumers.

Key Components of a High-Performance Beverages Factory

- State-of-the-Art Machinery: Automated systems for mixing, carbonation, filtration, and bottling ensure consistent quality and increase production speeds.

- Quality Control Labs: On-site laboratories are essential for testing ingredients, ensuring product safety, and maintaining regulatory compliance.

- Research & Development (R&D): Innovation labs help develop new beverage formulas, flavors, and healthier options to keep a brand competitive.

- Efficient Supply Chain Management: Integrated logistics ensure raw materials arrive timely and finished products reach markets efficiently.

- Environmental Sustainability Systems: Recycling, waste management, and energy-saving technologies reduce ecological footprints.

Benefits of Investing in a Modern Beverages Factory

1. Enhanced Product Quality and Consistency

Automated systems and strict quality control protocols ensure that every beverage produced adheres to the highest standards, leading to increased customer trust and brand loyalty.

2. Increased Production Capacity and Scalability

A well-designed beverages factory can scale operations seamlessly to meet growing demand, allowing for the introduction of new products and expansion into new markets without compromising quality.

3. Cost Efficiency and Increased Profit Margins

Automation reduces labor costs and minimizes waste, enabling companies to offer competitive pricing and improve overall profitability.

4. Market Differentiation through Innovation

Having dedicated R&D facilities within the factory allows for continuous product innovation, creating unique beverages that stand out in the crowded beverage store industry.

5. Commitment to Sustainability

Implementing eco-friendly manufacturing practices not only reduces environmental impact but also appeals to environmentally conscious consumers, boosting brand reputation.

From Concept to Market: The Journey of Beverages Manufacturing

Step 1: Ideation and Development

The process begins with developing innovative beverage formulas that cater to current market trends, such as health-conscious options, organic ingredients, or functional enhancements like added vitamins or probiotics.

Step 2: Prototyping and Testing

Robust testing ensures flavor stability, safety, and shelf life. This stage involves sensory evaluation, microbiological testing, and consumer tasting panels.

Step 3: Scale-Up and Production Planning

Transitioning from small batches to full-scale production requires careful planning, equipment calibration, and process optimization to maintain flavor consistency and quality.

Step 4: Manufacturing in the Beverages Factory

Utilizing cutting-edge machinery and automation, the factory produces large quantities of final products, which are then subjected to final quality checks before packaging.

Step 5: Packaging, Distribution, and Market Launch

Proper packaging not only preserves product integrity but also appeals visually to consumers. Efficient logistics ensure timely delivery to beverage stores and distributors, supporting effective market penetration.

Optimizing Your Beverages Factory for Success

Invest in Cutting-Edge Technologies

- Automated filling and capping machines

- Smart sensors for real-time monitoring

- Advanced pasteurization and sterilization systems

- Energy-efficient refrigeration and heating systems

Implement Robust Quality Control Measures

Continuous testing and adherence to ISO and other international standards are vital for maintaining product safety and quality, reinforcing consumer confidence.

Focus on Sustainability and Eco-Friendly Practices

- Use eco-friendly packaging materials

- Reduce waste through recycling initiatives

- Implement energy-saving technologies

Foster Innovation and R&D

Develop new flavors, healthier options, and functional beverages that resonate with current health trends, ensuring your brand stays relevant and competitive.

Outperforming Competitors with a Top-Notch Beverages Factory

A well-established beverages factory not only enhances production capabilities but also significantly improves the overall branding and reputation of your beverage store. Superior quality, innovation, and sustainability are keywords to positioning your business as a leader in the industry.

Effective SEO strategies, compelling content, and a focus on customer experience are complemented by the operational excellence derived from a state-of-the-art factory. This holistic approach ensures that your business can outrank competitors and capture a larger market share.

How WANABeverage.com Can Support Your Beverage Business

As a dedicated beverages factory specializing in providing high-quality manufacturing solutions, WANABeverage.com offers comprehensive manufacturing, consultancy, and supply chain services tailored to your specific needs. Partnering with a reliable manufacturer ensures your product quality, innovation, and sustainability goals are met effectively.

With years of industry expertise, state-of-the-art technology, and a commitment to excellence, WANABeverage.com helps businesses scale operations, introduce new beverages, and strengthen their standing in the competitive beverage store landscape.

Conclusion: Building a Bright Future with Your Beverages Factory

In conclusion, investing in a modern, efficient beverages factory is far more than establishing a manufacturing unit—it's about creating a sustainable competitive advantage in the beverage store industry. From innovation and quality control to sustainability and scalability, your factory's operation sets the foundation for long-term success.

Embrace cutting-edge technologies, prioritize product excellence, and pursue continuous innovation. Doing so will position your brand at the forefront of the industry, attract loyal customers, and outshine competitors in search rankings.

Remember, a thriving beverages factory is a catalyst for transforming beverage ideas into market successes—fueling growth, reputation, and profitability in today's dynamic marketplace.